HOME > Corporate Profile > Environmental Activities > Our Approaches for Resource Circulation

Our Approaches for Resource Circulation

Approach in Development and Design of Products

Approach in Development and Design of Products Approach in Manufacturing

Approach in Manufacturing Approach in Sales and Logistics

Approach in Sales and Logistics Collection and Recycling of Used Products

Collection and Recycling of Used Products Packaging Material Information

Packaging Material Information

Approach in Development and Design of Products

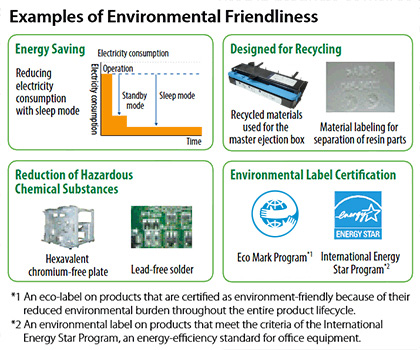

RISO KAGAKU CORPORATION endeavors to reduce the environmental burden of its products throughout their entire lifecycle, from design and development to production, distribution, customer use, recycling and disposal.

Policy on Research & Development

RISO's development and design philosophy is to "Create Unique Products." Over the years, RISO has developed a wide range of products that provide advanced print solutions based on its unique print technology, as typified by the RISOGRPAH System. In addition, RISO is aggressively undertaking R&D activities in new fields, including inkjet technology. Inkjet technology has been applied in the Company's new line of high-speed color inkjet printers, the ComColor series. Such an aggressive R&D stance has produced tangible results, enabling RISO to develop the latest RISO MF and SF series digital duplicators with a design that reduces the product's environmental burden, as well as other environment-friendly products, such as RISO RICEINK.

Process for Implementing Environmental Considerations into Products

RISO assigns five stages -- from element development to mass production.

In each of these five stages, RISO sets targets for such items as environmental considerations, product quality, costs and schedule. By monitoring the progress of these targets, we make decisions on whether we can proceed to the next stage.

Stage targets for environmental considerations include energy and resource saving, reuse, recycling and disposal.

Approach for Resource Circulation

"Used products are not wastes but precious resources" in RISO's view. We thus maintain a recycling system whereby we collect used printers or empty ink bottles, in a concerted move toward a recycle-oriented society.

To achieve this, we consider reuse during development and design.

Approach in Manufacturing

For the purpose of "Prevention of Global Warming" and "Effective Utilities of Resources", RISO promotes several activities, which include energy-saving or reduction of excretory products.

Waste Reduction

RISO promotes 3R(Reduce, Reuse, Recycle) activities to reduce waste generated through its operations. In particular, the Company focuses on the reduction of the amount of waste that is not recycled and is used for landfill.

Approach in Sales and Logistics

RISO KAGAKU CORPORATION attempts the reduction of CO2 emission or wastes, through switching to the transportation means of lower environmental loads, i.e., modal shifts and employment of reusable packing materials.

Reduced One-way Packaging

As part of efforts to reduce waste generation in logistics operations, RISO is increasing the use of returnable pallets, while decreasing the use of cardboard, Styrene foam and other disposable packaging materials.

Collection and Recycling of Used Products

"Used products are not wastes but precious resources" in RISO's view. We thus maintain a recycling system whereby we collect used printers or empty ink bottles, in a concerted move toward a recycle-oriented society.

Recycling of Digital Duplicators

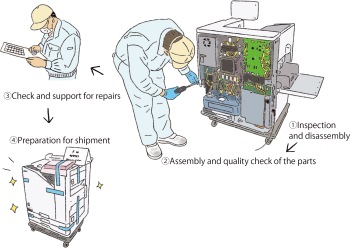

We disassemble digital duplicators collected from markets in Japan and separate them into consumable parts and reusable parts.

Consumable parts are replaced with new ones, while reused parts are inspected based on our quality assurance standards, and those that pass the standards are washed and cleaned before being used in products again. The assembled products undergo strict quality checks before being shipped as recycled products. For parts that cannot be reused, we outsource them to external companies and recycle them.

Reuse of High-Speed Inkjet Printers

Our high-speed inkjet printers collected from markets in Japan are disassembled and separated into consumable and reusable parts.

When used high-speed inkjet printers arrive at our parts center, we inspect, disassemble, and clean them to make them reusable parts except for some. After assembling them, we test them for printing quality. Then we have further checks and reship them after confirming no errors.

The Ministry of the Environment, focusing on approaches to improve the effectiveness of reused machines, has formulated "Guidelines for the Procurement of Environmentally Friendly Office Equipment", a fundamental item in a contract that should be prioritized and considered. It also recognizes the effectiveness of procuring reused equipment to reduce greenhouse gas emissions at the manufacturing stage and recommends procuring equipment with low power consumption during the use stage.

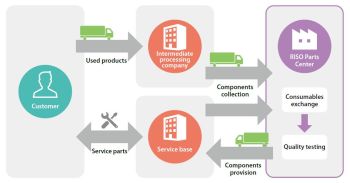

Convert Used Products and Components into Reusable Parts

RISO does everything possible to reuse products and components. Some components are collected for reuse and their consumables are replaced at the RISO Parts Center. They are then used again in the market after undergoing quality testing.

Material Recycling of Ink Bottles and Ink Cartridges

RISO collects used empty ink bottles and ink cartridges from users in Japan for material recycling* or thermal recycling, to effectively utilize resources.

*Material recycle:

Generally, recycling consists of two techniques: material recycling and thermal recycling. Material recycling refers to the processing of waste into more reusable materials. These recycled materials are used in new products.

Only conducted in Japan.

Only conducted in Japan.

Only conducted in Japan.

Only conducted in Japan.

Overseas Collection and Recycling

In France, since 2012 RISO has been contracting with CONIBI, a resource recycling firm established through joint investment with major business machine manufacturers, to strengthen collection and recycling of ink bottles and cartridges.

Packaging Material Information

Material information for promoting proper recycling