HOME > Products > Digital Screen Maker > GOCCOPRO Series Digital Screen Maker > A screen making system that's easy on the environment

A screen making system that's easy on the environment

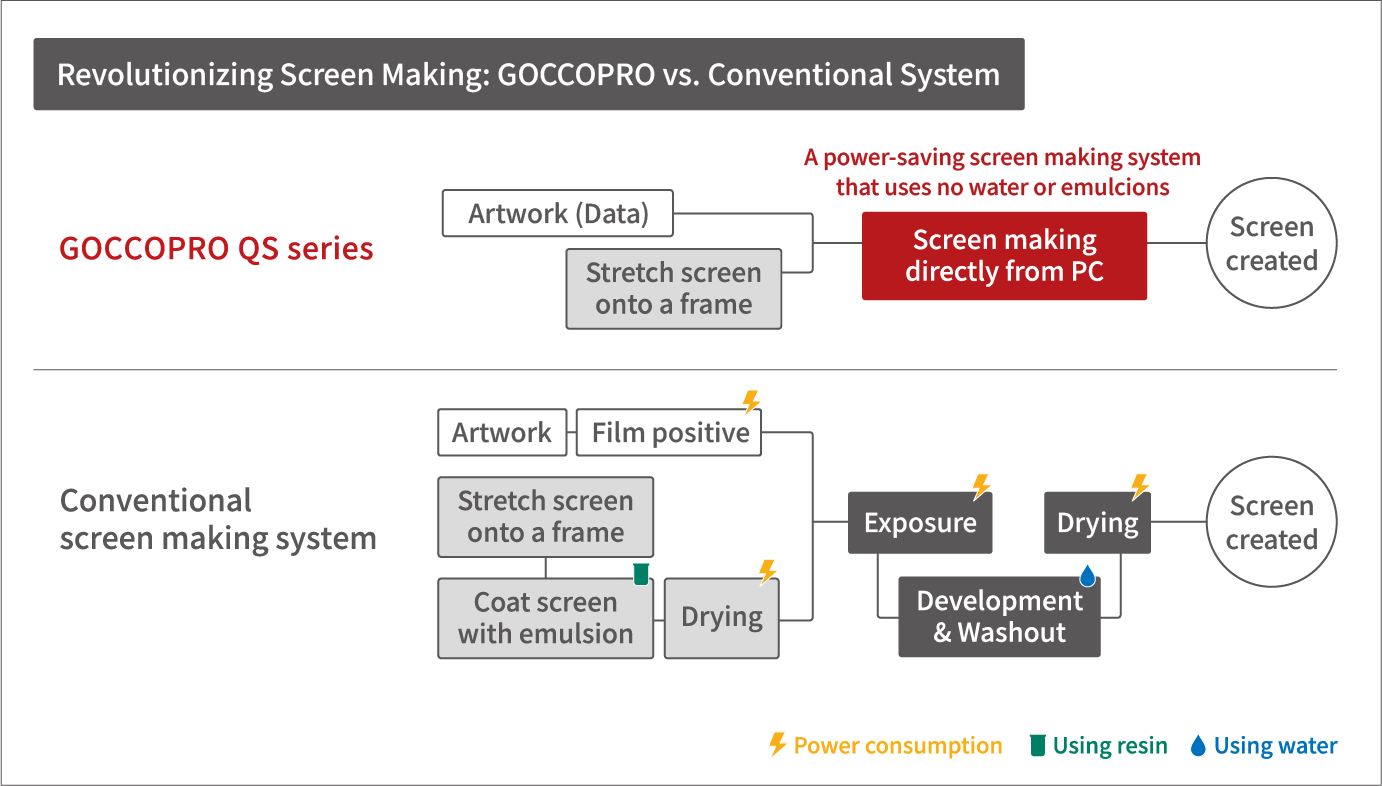

RISO's digital screen maker, the GOCCOPRO series, enables a digital screen making method that is easier on the environment than conventional screen making system. Eliminating the need for emulsions also eliminates the washout step.

- No need for water

- Minimal resin consumption

- Reduced power consumption

- Achieve Environmentally Green Screen Printing with GOCCOPRO Series

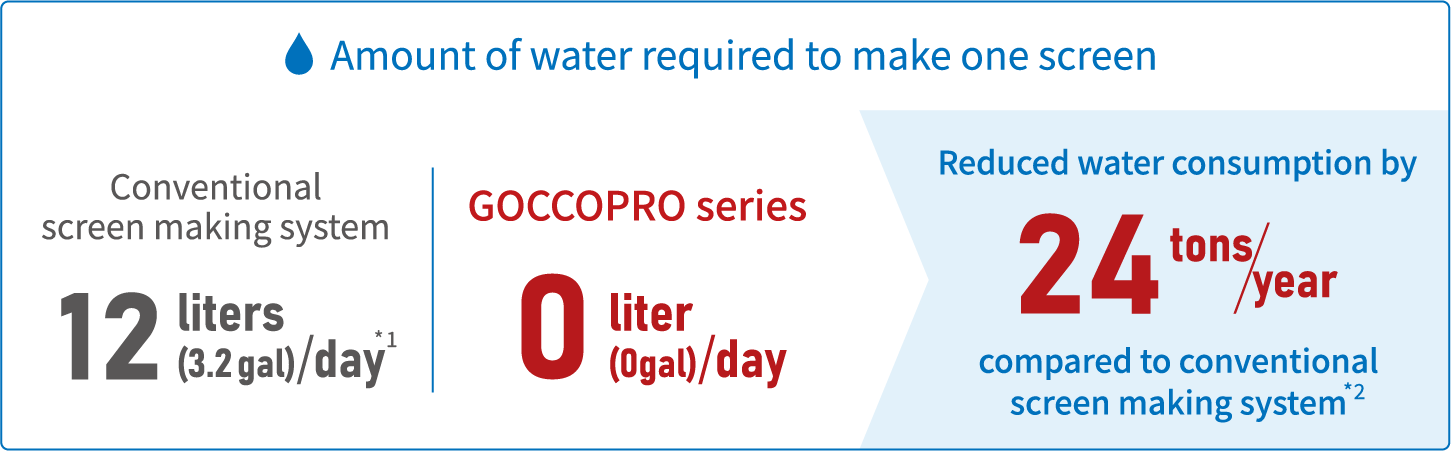

No need for water

The GOCCOPRO series uses digital-based thermal technology, eliminating the need for exposure and washout.

This eliminates approximately 12 liters (3.2 gal) of water used per plate for conventional screen making system. By eliminating the use of water, the GOCCOPRO series contributes to the reduction of environmental impact.

- *1:In case 3 liters (0.79 gal) of water per minute is used for screen making of one A3 size screen.

- *2:In case of A3 size screen making 10 times a day, operating 200 days a year.

Minimal resin consumption

The GOCCOPRO series of digital thermal screen making systems do not use emulsion. The amount of resin consumed per screen for conventional screen making system is 10.0 g (0.35 oz), but with the GOCCOPRO series, this amount can be significantly reduced to 0.4 g (0.014 oz). This reduces the consumption of valuable resources.

- *1:The resources required to make one A3 size screen.

- *2:In case of A3 size screen making 10 times a day, operating 200 days a year.

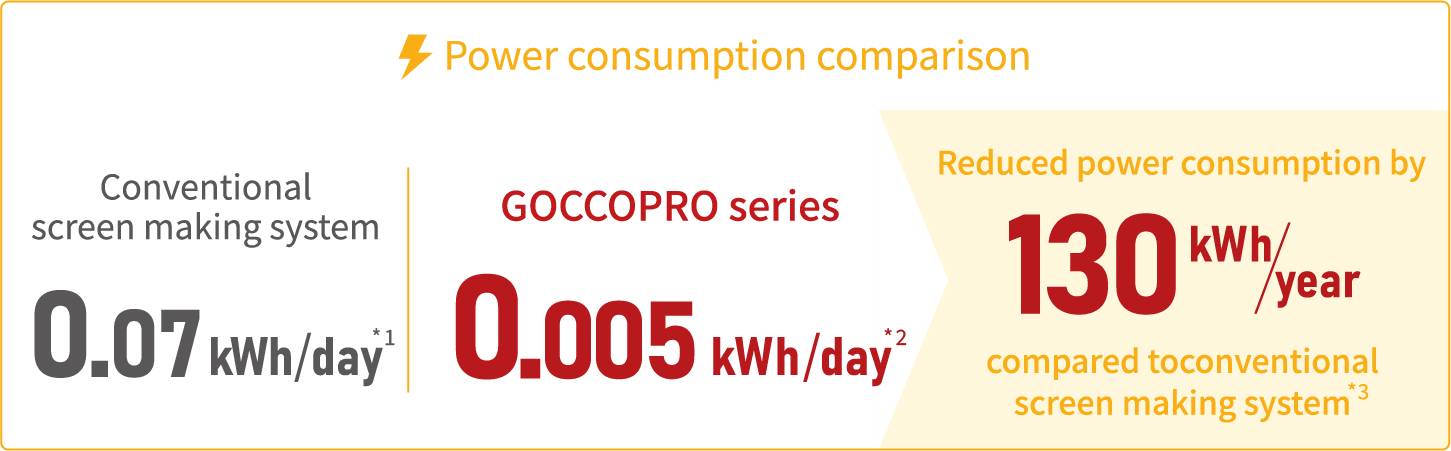

Reduced power consumption

The GOCCOPRO series does not require the positive film output, exposure, and drying processes necessary with the conventional screen making system.

As a result, compared to the 0.07 kWh*1 electricity used for emulsion screen making per day, the GOCCOPRO 100 requires only 0.005 kWh*2, resulting in a significant reduction in electricity consumption.

- *1:Calculated assuming that each of the processes required for screen making of one A3 size screen - positive film output, exposure, and drying - consumes 2 minutes of electricity each.

- *2:Power required for screen making of one A3 size screen is calculated; please contact us for the electricity consumption of GOCCOPRO QS series.

- *3:In case of A3 size screen making 10 times a day, operating 200 days a year.

The GOCCOPRO series is an environmentally friendly and efficient solution.

The GOCCOPRO series digital thermal screen making system eliminates the need for emulsion, significantly reducing the use of water, resin, and electricity. It also offers simple, one-touch operation, just like using a printer, making the process highly efficient. Screen making process and working hours are also greatly reduced, contributing not only to environmental friendliness but also to TCO*1 reduction.

- *1:Total Cost of Ownership