HOME > Products > Digital Screen Maker > GOCCOPRO Series Digital Screen Maker > GOCCOPRO QS1836 features

GOCCOPRO QS1836 features

Main Features of the GOCCOPRO QS1836

- No screen making experience required

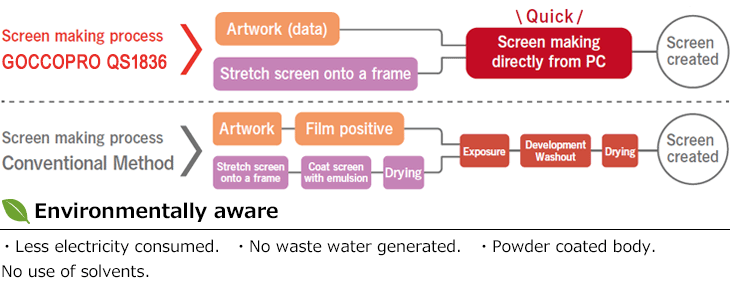

- Work directly from computer to screen

- Eliminates steps like exposure and drying

- No need for darkrooms and washout booths

- No need to store large number of screens

- Compact size fits on a table

- Corresponds to narrow frames resulting in lower screen master cost

- Outsourced jobs can be profitably completed in-house

- Perfect for short-run printing and test production

- No need for emulsions and washout

- Dry screen making process with thermal screen technology

Digital Screen making process

RISO Dry Thermal Screen Making System is a CTS* system with a thermal head that heat-perforates a screen master of mesh laminated with film. Enables low-cost, speedy screen making even for sample and small-lot production, and across a wide range of jobs, from multi-color T-shirts to name plates.

* Computer To Screen